"Services"

Quality Assurance Dept.

Early detection of defective items

Early Detection of Defective Products

We have established a system for the early detection of defective products, spanning from the production review stage to shipment.

High-quality products are delivered through a combination of mechanical and manual inspections.

Business Areas

Quality Assurance System

In-process inspection

The Quality Assurance Department plays a central role in establishing a system for the early detection of defective products.

Dimensions not indicated on drawings are also verified using 3D data and compared against measured values.

Acceptance test

We respond promptly and flexibly to issues as they arise through our rapid inspection system.

Outgoing inspection

Quality is assured through inspections for dimensional accuracy, shape, and appearance.

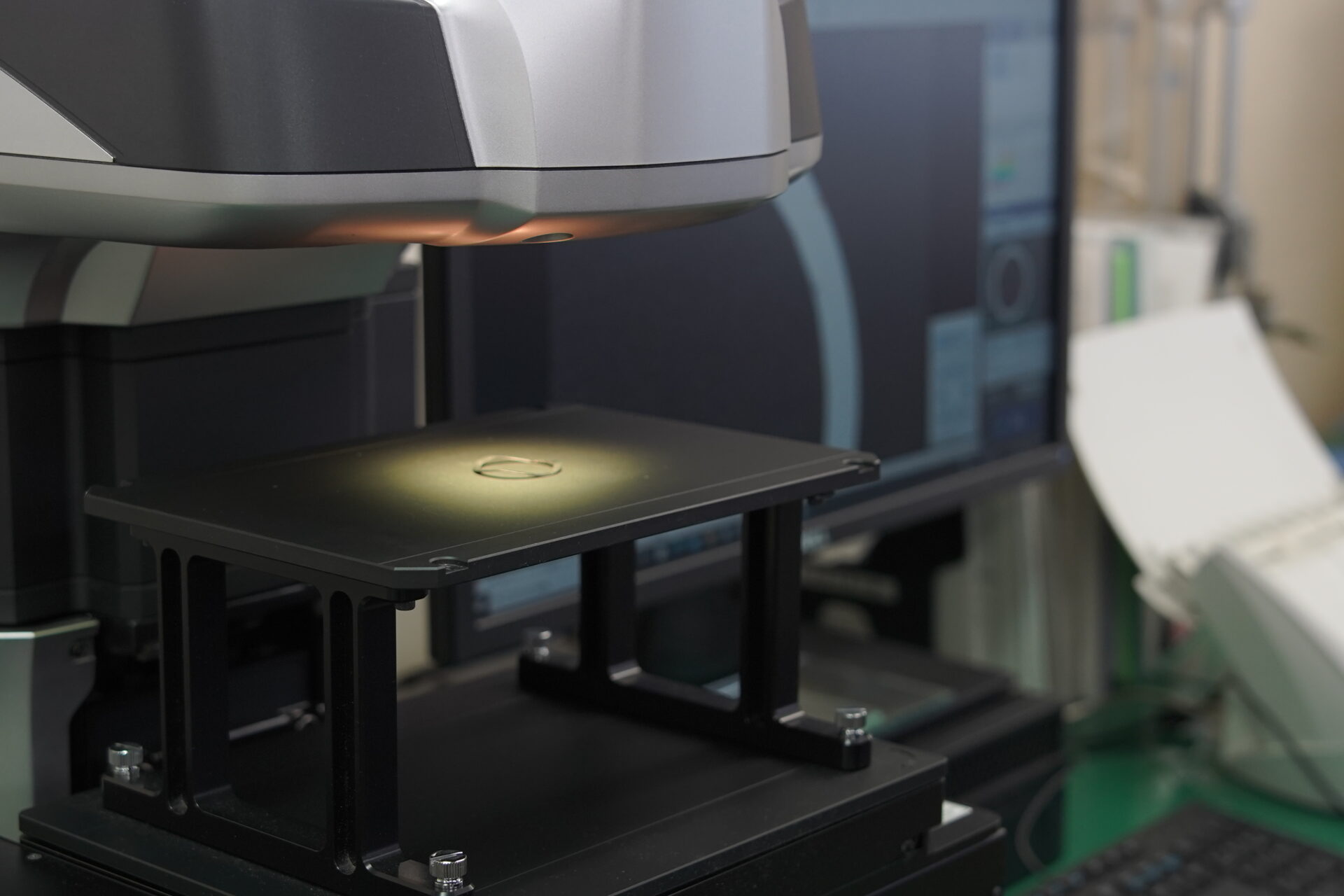

Upon customer request, additional inspection items can be accommodated using image measuring instruments.

Movable door sill

Tray packaging is available upon customer request.

inspection equipment

3D Shape Measuring Instruments

Keyence VR5000

Image dimension measuring machine

QVI StarLite250 Keyence IM-8000

Measuring Microscope

Nikon Kouken Type 10, 2 units

Nikon MM-400

Nikon MM-400

spring tester

Showa Testing Machinery SH-N5

Surface Roughness Measuring Machine

Mitutoyo SJ-410

Projectors

Mitutoyo PJ-H30D2010B

Nikon V-16E

Nikon V-16E

Hardness Tester

Akashi MVK-G1

Torque tester

IMADA eHT-5N

Well-equipped inspection equipment

Fully equipped with a comprehensive range of testing equipment.

Quality inspection is the most critical process for our company, which specializes in the manufacturing of precision instruments and components.

Our inspection equipment is regularly updated to enable high-precision inspections.

Furthermore, to detect errors that cannot be identified by machines alone, we rely on the expert eyes of skilled craftsmen to ensure that no defects go unnoticed.